Flexibility and efficiency

Nelden Industry’s canning lines combine Nelden’s own filling monoblocks with a multitude of packaging solutions, designed to handle a wide range of products by perfectly adapting to different outputs and marketing needs.

Available in different sizes, Nelden plants can handle production capacities ranging from 2,500 to 80,000 cans per hour, depending on the type of product and the size of the containers.

Low maintenance requirements: thanks to sevaral technical measures aimed at automation, including the absence of can lifting jacks and electronic management of each filling phase, human intervention is reduced, minimising machine downtime.

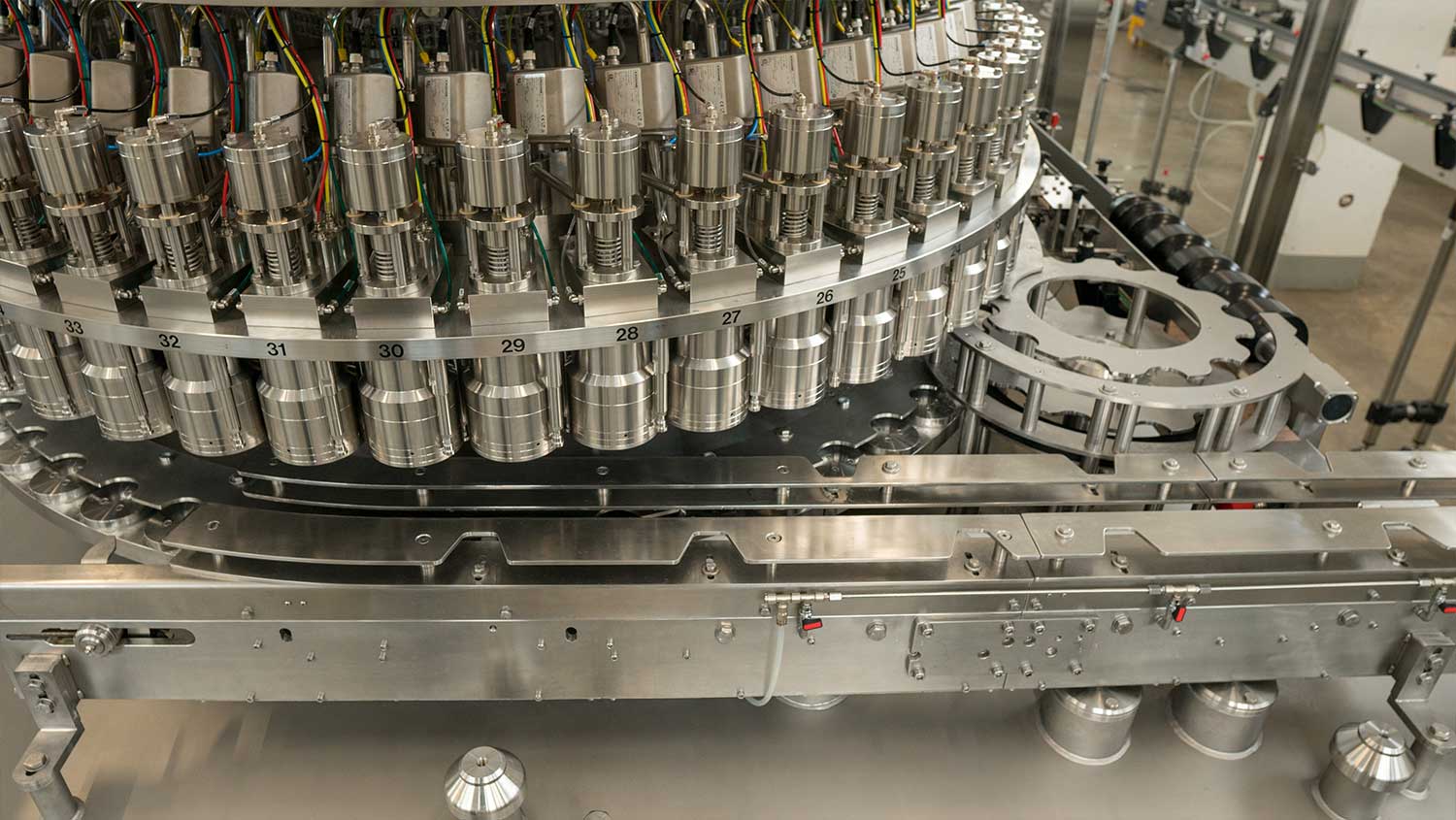

The core of the filling solution proposed by Nelden however is the electronic filling valve with volumetric product dosage.

This innovative system allows to easily change the can and lid format without having to modify or replace the valve. A solution that increases flexibility and reduces set-up times, making Nelden fillers ideal for handling a large number of formats.

All filling phases can be customized according to the specific product, adjusting times and parameters to always guarantee maximum filling precision.

PRODUCTS SUITABLE FOR URANO CANS

- Still water, sparkling water

- CSD

- Energy Drinks/Isotonic drinks

- Beer & Malt Drinks

- Still wine

- Sparkling Wine

- Cider

- Clear juices

- and juices with fruit pulp

SOLUTIONS FOR EVERY PRODUCT

Our filling solutions offer maximum versatility to handle a wide range of products.

We use the VOLUMETRIC ISOBARIC SYSTEM,

ideale sia per bevande frizzanti che piatte,

garantendo un riempimento preciso e sicuro.

For those who need hot filling, we offer an efficient system at 85°C, equipped with continuous product recirculation. This system is supported by an external tank and modulating valves, ensuring perfect control of the temperature and flow of the liquid during the entire process.

If the product contains pulp, we are able to handle particles up to 0.5 mm in diameter and 5 mm in length, maintaining the quality of the content intact.

Furthermore, for it is possible to add a pre-dosing system of solid content inside the can before liquid filling, which can be done at controlled hot filling high temperatures, allowing to treat products with pulp of considerable dimensions (e.g. 10x10 mm) according to the customer’s needs.

Available on all sizes :

“ULTRACLEAN” configuration on all versions of the monoblock, consisting of:

- HIGH CLEARING inclined base in AISI 304 stainless steel

- Full protection: complete upper closure, in addition to the CE perimeter protections.

- Laminar flows – pressurized chamber via laminar flows (HEPA filters)

- Parts in contact with the product in AISI 316 stainless steel